Accurate Stockpile Analytics for Sand and Gravel Operations in Southwest Ohio

- chrisblanchard5

- Dec 5, 2025

- 3 min read

Accurate Stockpile Analytics for Sand and Gravel Operations in Southwest Ohio

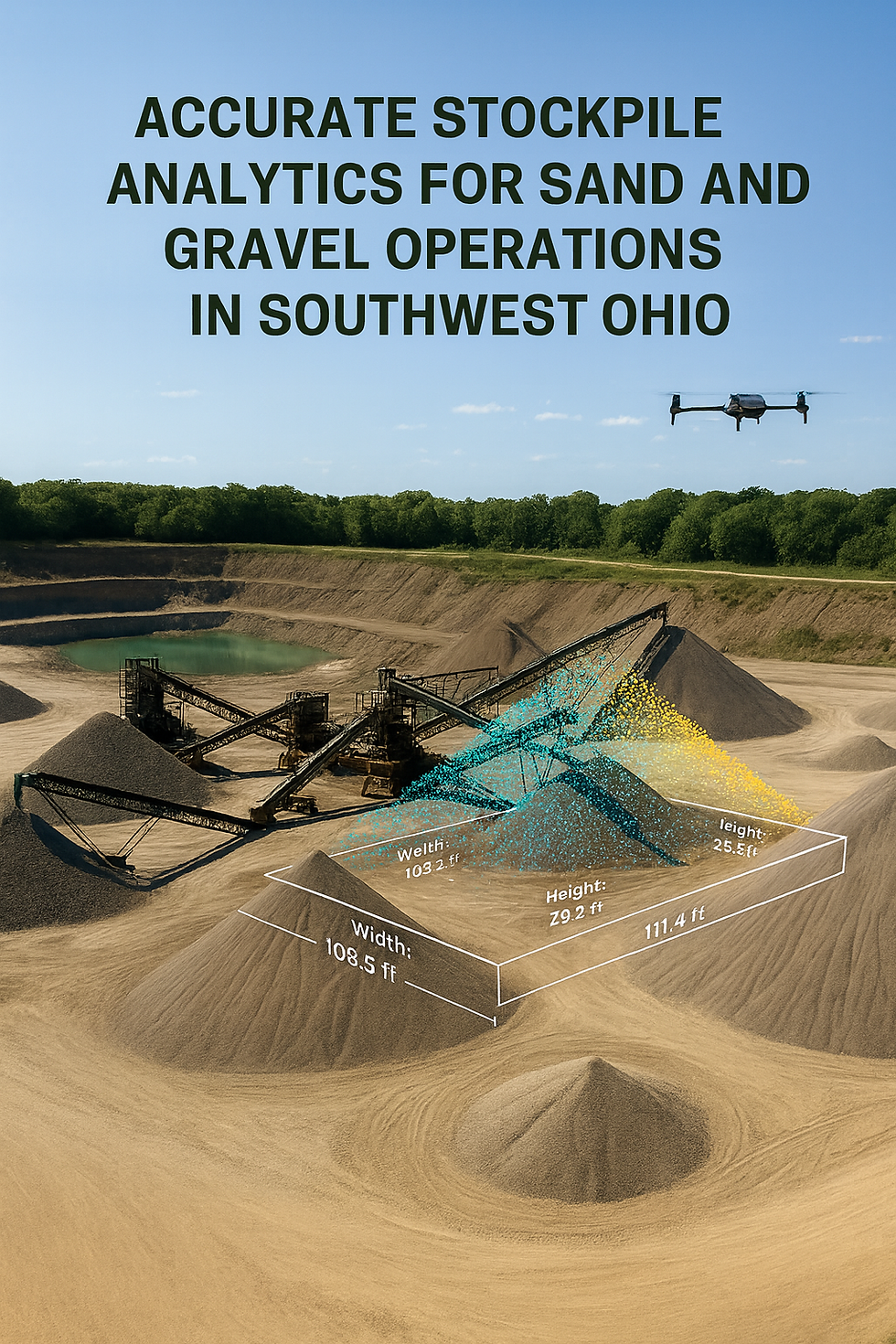

In the sand and gravel industry, every decision begins with a clear understanding of available material. Production schedules, sales forecasts, equipment planning, and financial reporting all depend on knowing exactly how much inventory sits on the ground. For mines across Southwest Ohio, this challenge becomes even more significant due to the variety of aggregate sizes, irregular pile shapes, and the constant movement of material. At HoverPoint Drones, we provide stockpile volumetric analysis that delivers the reliability and consistency operators need to run their businesses with confidence.

Modern drone based volumetrics have transformed how mine operators measure and manage inventory. Traditional methods often rely on walking piles with GPS equipment or estimating volumes by eye. These practices are not only time consuming but also prone to significant errors. The result can be inaccurate production reports, unexpected shortages, and costly financial discrepancies. Drone based stockpile analytics eliminates these uncertainties through repeatable and precise data collection that captures every contour of a pile from above.

The technology we use at HoverPoint Drones produces high resolution three dimensional surface models that reveal exact pile geometry. Instead of sampling a few points on the ground, our flights collect thousands of data points across the entire surface. This level of detail allows for accurate volume calculations even on steep slopes, complex pile shapes, or tightly packed inventory rows. Mines in Butler, Warren, Hamilton, and Clermont Counties can rely on these measurements regardless of the size or orientation of their stockpiles.

Consistency is equally important. When reporting inventory month after month, the data must follow the same methodology to ensure trends and comparisons remain valid. Drone based volumetrics allow us to repeat the same flight paths and processing methods at each visit. This creates a dependable historical record that improves forecasting, budgeting, and end of year reconciliation. Operators gain a clear view of production efficiency and material flow without worrying about measurement drift or human error.

Safety is another reason many mines are moving away from manual measurement approaches. Walking uneven piles, climbing loader tracks, or navigating active load zones increases the risk of injury. Drone flights eliminate the need for workers to physically access dangerous areas. Our team collects the data from safe ground positions while maintaining full visibility of site operations. This improves compliance with safety requirements and reduces potential liability.

The return on investment for professional stockpile analysis is significant. Accurate volumes prevent overordering and underproduction, ensuring that material supply aligns with sales commitments. Clear reporting reduces disputes with customers and brokers, since every number is backed by verified imagery and centimeter level modeling. Many operators also discover meaningful savings during their annual audit, since reliable drone data removes guesswork and supports clean accounting.

Operational efficiency improves as well. With rapid turnaround times, mine managers receive reports quickly enough to make immediate production decisions. Trends in pile growth or reduction become clear at a glance, providing better control over site activity. When planning equipment usage, staffing, or expansion, accurate volumetrics provide the foundation for informed strategy.

At HoverPoint Drones, our goal is to deliver stockpile analytics that enhance performance, strengthen financial accuracy, and support safe operations across Southwest Ohio. Whether your site moves a few thousand tons each month or operates at high volume year round, reliable and consistent measurement is the key to staying competitive. A professional stockpile analysis report provides the clarity needed to make confident decisions every day.

If your sand or gravel operation is ready to modernize its inventory measurement process, we are here to help. Our team provides precise, repeatable, and actionable volumetric data that supports the long term success of your mine.